Our Expertise in Complex Assemblies: How We Bring It All Together Under One Roof

When a customer comes to CAMM Metals with a complex assembly, they’re looking for more than just a vendor that can get the job done; they’re seeking out a manufacturing resource that can take a project from start to finish, bringing together multiple capabilities under one roof. With skills ranging from CNC machining and laser cutting to precision sheet metal fabrication and welding services, we have the machining talent and engineering expertise to complete intricate projects without a hitch.

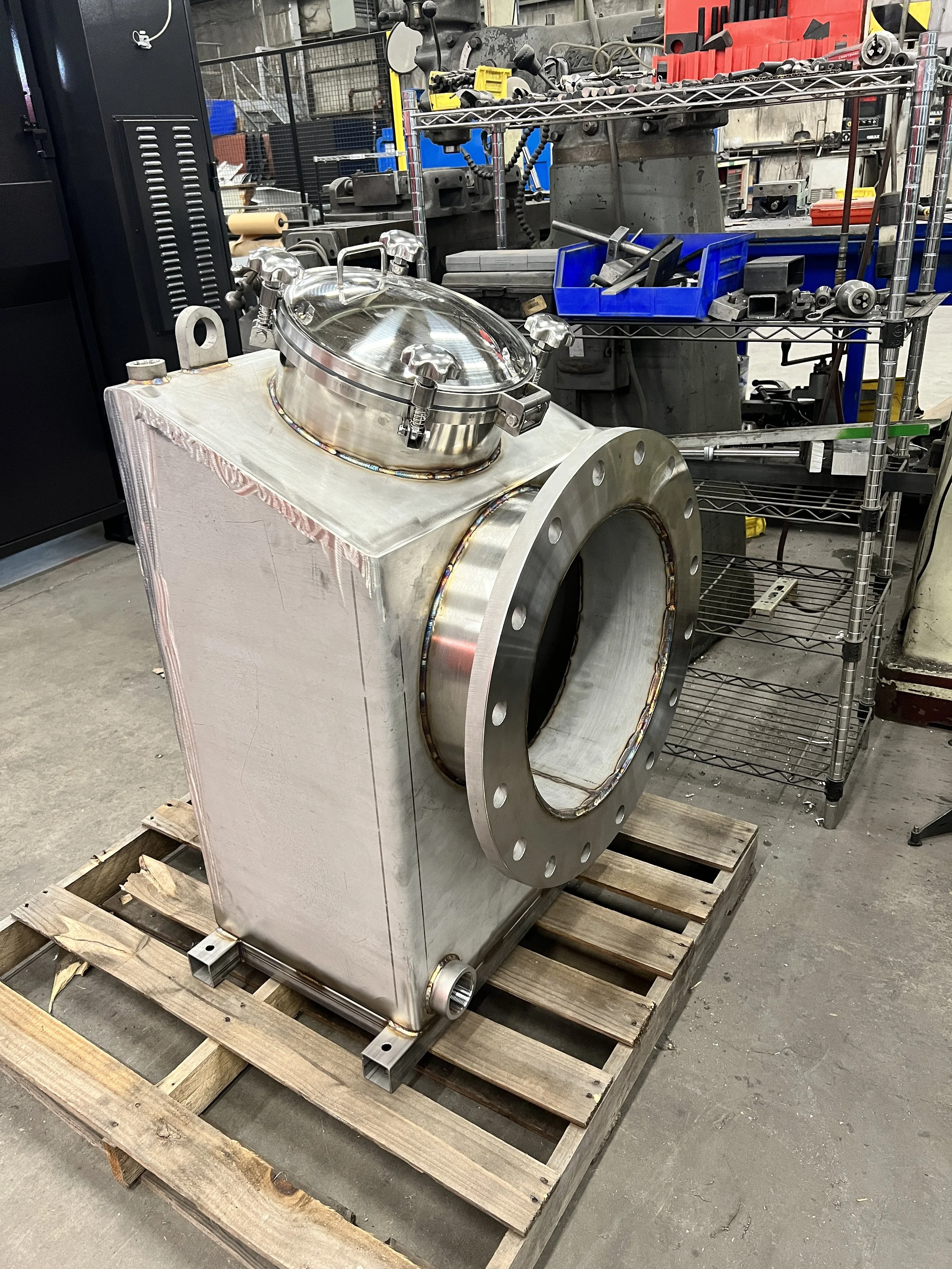

The Project: An Ultraviolet Tank

One standout project that demonstrates our expertise in complex assemblies was an ultraviolet tank built for a municipal water treatment system. This tank, which was 20 feet long and approximately three feet wide, was fabricated from 316 stainless steel. It serves a highly critical purpose of exposing water to ultraviolet light that cleans it and makes it potable by the time it spans from one end to the other.

Our customer required a contract manufacturer that could handle every step in-house to ensure proper fit and functionality. By building the entire assembly here at CAMM Metals, we were able to test all the components together instead of piecing them together later. That way, we could streamline the process and yield the highest level of quality possible for the customer.

Our Commitment to Your Success, from CAD to Completion

Before a project like this hits the shop floor, our engineering team plays a critical role. Using CAD software, we break down the assembly into all of its components and ensure each piece will fit together seamlessly. All in all, the process includes:

Verifying that all designed parts can be folded and unfolded correctly in both Paperless Parts and Autodesk® Inventor®, two software solutions that have proven invaluable to our engineers

Ensuring holes will be laser cut to the correct size for tapping

Checking joint designs for proper weld penetration after bending

Aligning hardware placement for accurate assembly

For this ultraviolet tank, this process involved approximately 60 to 70 individual parts, each of which our engineers reviewed for accuracy and manufacturability. This rigorous engineering process, which took roughly two weeks, was critical to ensuring that when production began, there would be no surprises in production.

The Value of In-House Capabilities

One of the main benefits of producing complex assemblies at CAMM Metals is that our team handles everything in-house. Our one-stop approach means:

Consistent quality across all stages of production

Reduced lead times by eliminating outside vendor delays

Better communication between engineering, fabrication, and machining teams

Full accountability for the finished product

Ready to Hand Off Your Next Complex Assembly Project?

If you have a job that requires multiple fabrication processes, precise engineering, and a single point of contact from start to finish, CAMM Metals is here to help.

Request a quote to partner with a fabrication shop that’s dedicated to the success of your complex assemblies.