6 Tips to Streamline Your Next Sheet Metal Assembly Project

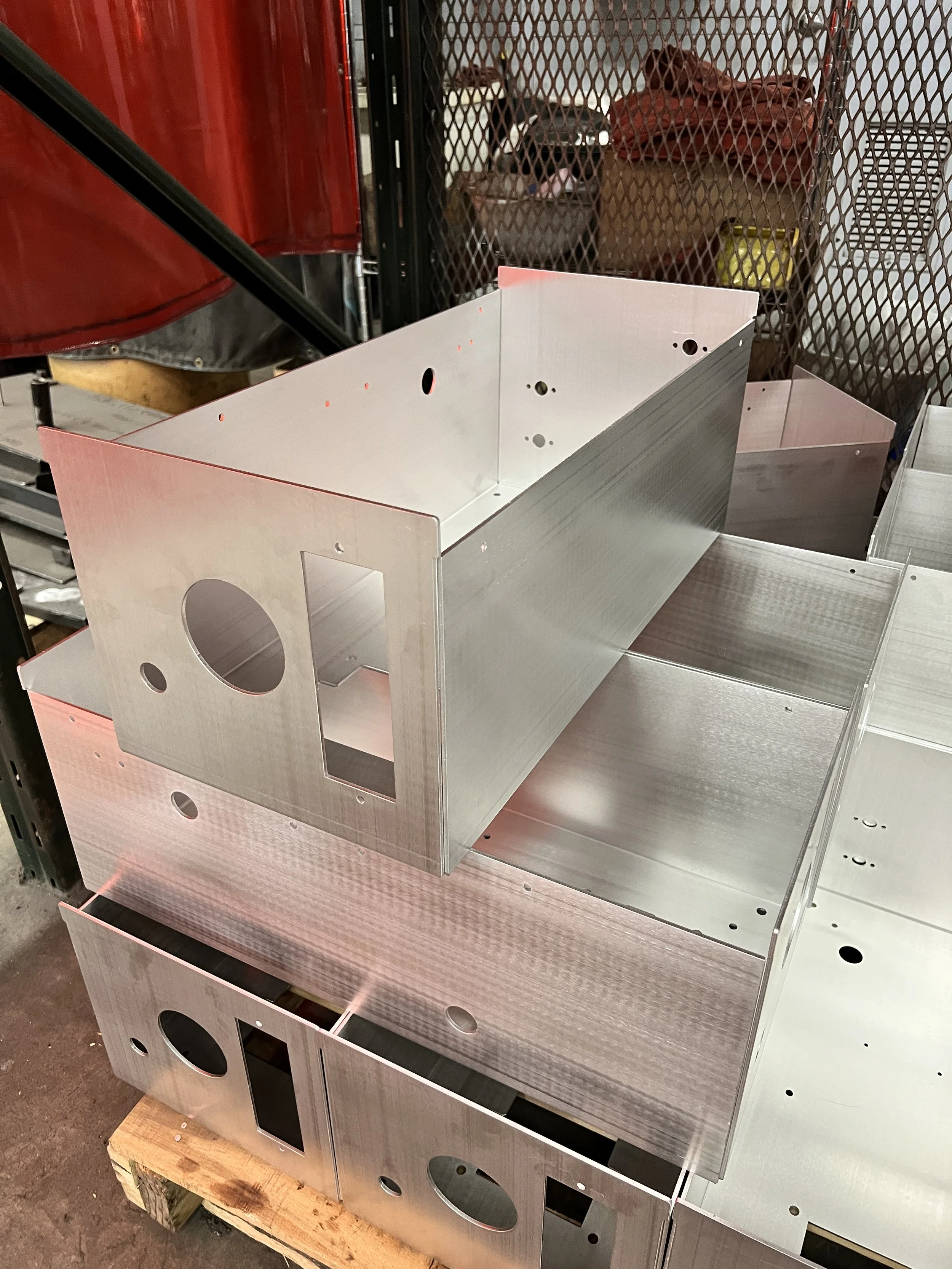

When it comes to building complex products, successful sheet metal assembly starts long before a single part is fabricated. At CAMM Metals, we’ve seen firsthand how thoughtful design can save time, money, and rework, especially in projects that combine multiple fabrication processes like laser tube cutting, bending, welding, and hardware installation. Here are six of the most valuable strategies we’ve learned for ensuring successful assembly.

Key Design Tips for Better Sheet Metal Assembly

1. Start with an accurate STEP file

When customers visit our fabrication shop and ask what they can do to set their project up for success, our first piece of advice is always the same: provide the optimal STEP file. It may sound simple, but having a clean, reliable model of the assembly enables every downstream process, from programming our machines to ensuring a proper fit during final assembly.

A solid STEP file helps us:

Unfold and generate a flat pattern

Simulate bending operations

Identify interferences before cutting or forming

Ensure tooling availability for our precision fabrication services

2. Understand machine capabilities

Not every design that works in CAD can be manufactured. We’ve seen customer designs push the limits of what our machinery can do, sometimes unintentionally going beyond what’s possible. That’s why we invite customers to visit CAMM Metals and see our equipment in action. A firsthand look at our facilities and machinery helps customers understand what’s feasible and where designs may need adjustment.

3. Design sheet metal parts as sheet metal parts

It sounds straightforward, but we cannot stress enough just how unique sheet metal parts are. They need to be drawn in a way that accounts for unfolding and forming functions. If a part isn’t designed with sheet metal principles in mind, we may need to reengineer it entirely to make it work, adding unnecessary time and cost.

4. Keep tolerances realistic

Metal fabrication has its limitations. While CNC machining may allow for tighter tolerances, sheet metal parts should typically be designed with looser tolerances to account for material variability and forming processes. Be cautious when using machining surface finish callouts; they don’t always translate to sheet metal.

5. Avoid tolerance stacking

In large assemblies, small tolerance misalignments can stack up and create big issues. Always consider how each part contributes to the whole and where some wiggle room may be beneficial. We’ve seen many situations where a tiny oversight resulted in a bolt not fitting or a bracket needing to be modified on-site—the last thing our customers want to deal with near the end of a project.

6. Share the bigger picture

It helps when our team understands not just the part we’re making, but the entire assembly it fits into. If we know how the end product works—what’s bolting to what, where the weldments fit, and how the part is used—we can make better recommendations, avoid surprises, and ensure the final product works as intended.

Partner with CAMM Metals for Your Sheet Metal Assembly

At CAMM Metals, we’ve been building high-quality assemblies for over 25 years. Our team uses advanced modeling tools and software to view 3D files, simulate movement, and anticipate any issues before they hit the floor. And, most importantly, our customers trust us not just for parts but for partnership.

Looking to streamline your next sheet metal assembly? Let CAMM Metals deliver your product with the experience, technology, and insight to get it done right.