Welding

Welding Services for Precision, Durability, and Quality

Producing the Best Results with Certified, Tested Welds

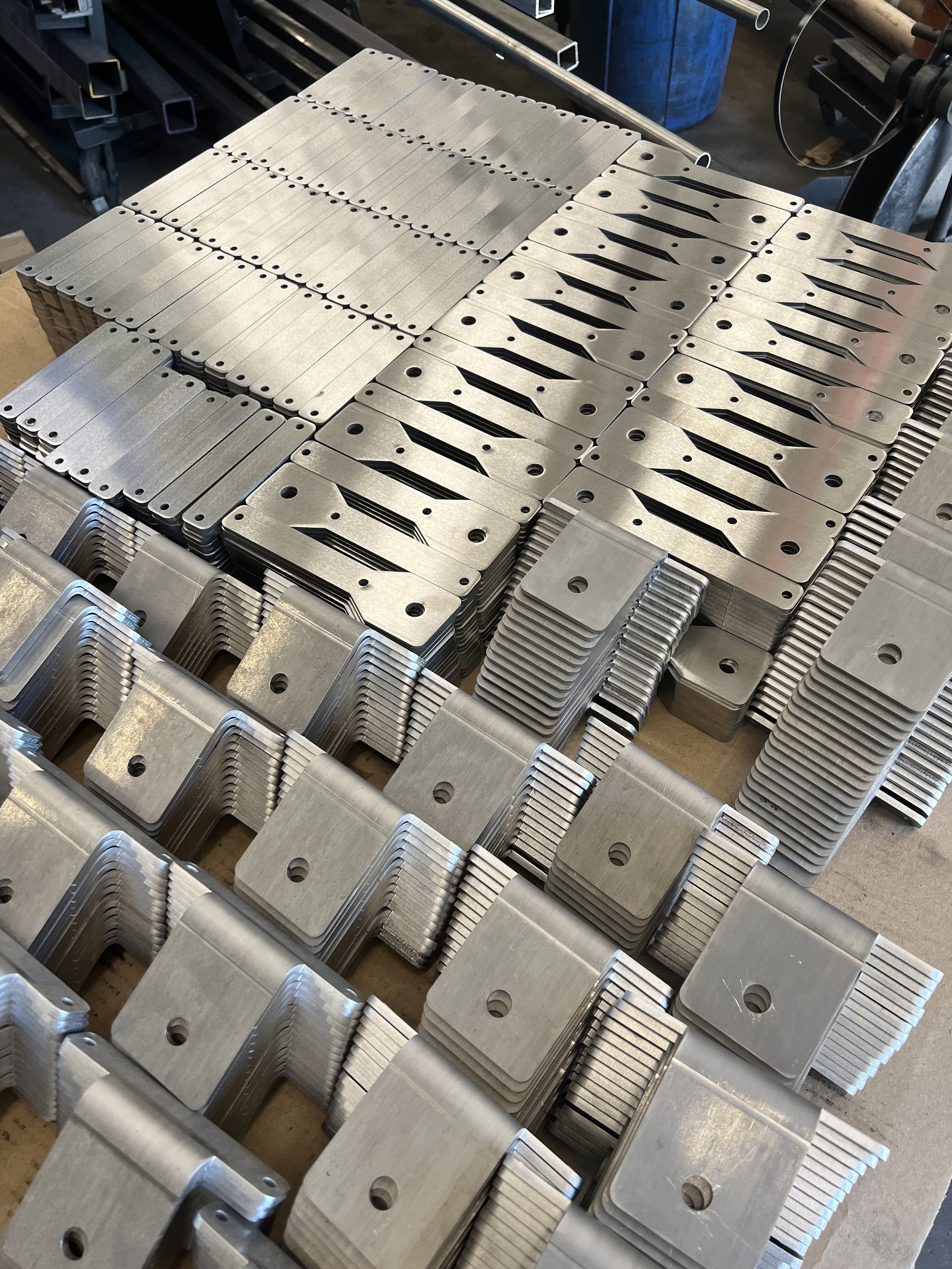

At CAMM Metals, our team specializes in MIG and TIG welding techniques. Whether working with steel, stainless steel, or aluminum, our skilled welders ensure precise and durable welds that meet the highest quality standards.

The Benefits of CAMM Metals’ Welding Services

With a range of welding equipment and talented welders, CAMM Metals offers exceptional results on welded components. Our customers gain value from our welding services in the following ways:

-

Our welders use precision-ground welding tables, which play a crucial role in ensuring that parts are built square and with exceptional accuracy. Additionally, at CAMM Metals, we leverage our 3D printing expertise to develop custom fixturing that we use alongside processes such as our welding services.

-

We offer certification to AWS D1.1 and AWS D1.6 standards for customers who require certified welds. Our adherence to these rigorous standards ensures that each weld meets the stringent criteria for guaranteed strength and quality.

-

At CAMM Metals, we take great pride in ensuring top-notch quality in every one of our sheet metal fabrication services. That’s why we offer add-on services such as dye penetrant testing for weld inspection. For example, when projects involve enclosures that need to hold liquids, our team conducts this testing to ensure watertight integrity.

Understanding a part's final application is critical to delivering the best results. Our estimator works closely with customers to determine each project's optimal welding techniques and testing procedures. Whether advising on the correct type of weld or recommending testing protocols, our team is here to help. Don’t hesitate to contact our team with any questions or concerns.

Request A Quote for Welding Services

Partner with CAMM Metals for versatile sheet metal fabrication services. We’re your single-source supplier for sheet metal cutting, bending, fabricating, and welding services.