Expertise Matters in Hardware Insertion Operations

Although hardware insertion seems like a simple step performed at the end of the process, it’s actually one of the more detail-driven operations that can make or break the performance of a finished part.

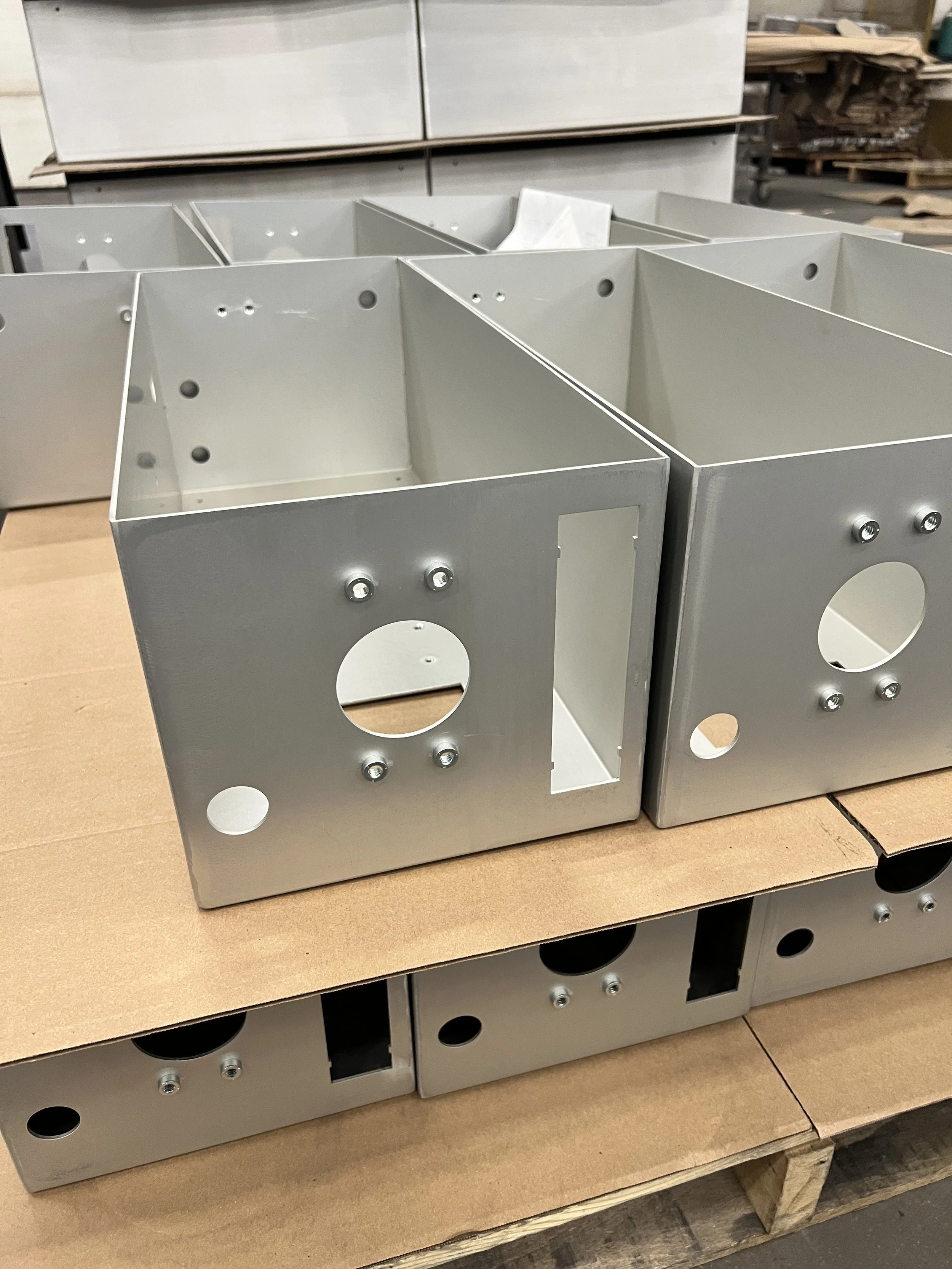

At CAMM Metals, we handle hardware insertion capabilities every single day. We understand that installing PEMs and other fasteners requires deep material knowledge and close coordination with upstream and downstream processes. Our attention to detail and expertise ensure we handle it correctly the first time.

Let’s explore this capability and where our expertise is critical.

Understanding Material-Specific Requirements

Not all hardware is created equal

One of the biggest misconceptions we see is that hardware components are interchangeable across materials.

Installing hardware into stainless steel is very different than inserting it into aluminum or carbon steel. Each material requires specific fastener designs, grip ranges, and installation forces. Even minor variations in hardware selection can lead to improper fits or part failure.

Our team reviews RFQs carefully and frequently catches instances where the wrong PEM has been specified based on the required material. When that happens, we will flag this issue and recommend the correct hardware so our customers can update their drawings.

The impact of finishing processes on hardware insertion techniques

Another critical factor is how finishing operations affect hardware. Certain plating and coating processes can damage PEMs if they’re installed too early.

For example:

Anodizing can damage installed hardware, so insertion must occur after.

Chem film coating requires stainless steel PEMs, as standard steel hardware will not survive the process.

These details are easy to overlook if you’re not immersed in a fabrication shop environment every day like we are. Our direct experience allows us to identify these risks early, before they turn into costly rework or delayed deliveries.

Early Review Makes a Difference

Hardware insertion touches multiple stages of production, from metal fabrication and CNC machining services to finishing. If hardware requirements aren’t considered upfront, problems can surface later on when changes are harder and more expensive to make.

By reviewing designs early in the process, our team ensures that:

Hardware is compatible with the base material

Finishing processes won’t compromise fasteners

Installation sequencing is optimized

Parts are fully functional when they leave our facility

This proactive approach underscores the value of partnering with an expert like CAMM Metals.

The Value of One-Stop Fabrication Services

Because CAMM Metals offers hardware insertion alongside services such as welding and laser tube cutting, we eliminate unnecessary handoffs between vendors. That means better communication, tighter quality control, and faster turnaround times for our customers.

In many cases, we also perform light assembly after hardware insertion, ensuring parts are truly production-ready when they ship.

Trust CAMM Metals, a Partner and Expert in Hardware Insertion

Hardware insertion plays a critical role across many of the custom fabricated components we produce. The precise capabilities we perform directly influence the hardware we choose. In addition, how it’s installed directly impacts fit, strength, and long-term functionality.

By combining experience and attention to detail, CAMM Metals ensures every component meets functional and quality expectations. That’s what it means to partner with a shop that understands the nitty-gritty and finer details.

Do you have a project that requires hardware insertion? Request a quote to partner with our expert team.